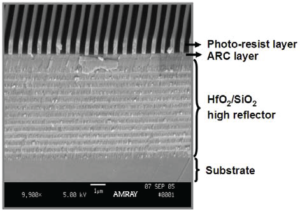

Large area Multilayer Dielectric (MLD) diffraction gratings are essential components for temporal pulse compression in high energy laser systems. MLD grating designs typically consist of a silica grating layer on top of a dielectric multilayer reflector. A reactive ion beam etching (RIBE) process using a gridded radio frequency (RF) ion source was developed to uniformly etch the silica grating layer through a binary photo-resist mask on large size optics. The reactive etching is performed in two steps to sequentially remove different layers of materials. The RIBE system utilizes a unique substrate translation mechanism to achieve a uniform etch on large optics. An optical photometer is used to monitor both the grating product and witnesses to determine the etch endpoints. Using this process, MLD diffraction gratings of 1740 lines/mm groove density on optics up to 920 mm (length) × 410 mm (width) × 100 mm (thickness) have been uniformly etched with averaged diffraction efficiency greater than 85% and wavefront flatness less than 0.18 waves.While this process has been successful, there is a current etching problem which is discussed below.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com