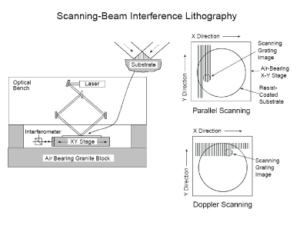

Large area multilayer-dielectric (MLD) gratings for high energy pulse compression have been manufactured using a new exposure method called scanning beam interference lithography (SBIL). This technique uses two small beams to form a small area of low distortion, high contrast fringes. The fringes in this small area are phase-locked to a substrate on an x-y stage. As the stage and substrate are scanned underneath the illuminating fringe-spot a resist layer is exposed. The diagram at right shows the fundamental operation of the system. Light from a laser is split into two beams which recombine to form fringes at the substrate (the details of the fringe-locking system are omitted from this diagram). A position-sensing interferometer monitors movement of the substrate stage. The fringe phase is controlled to be stationary with respect to the substrate. Any number of scanning methods may be used but most common (shown) are parallel scanning in the fringe direction and Doppler scanning perpendicular to the fringe direction. The device used to form the fringes, perform the fringe-locking, and scan the substrate is called a Nanoruler.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com