PGL employs sophisticated, state-of-the-art design tools for modeling diffraction grating and thin-film coating performance. These are vital not only for determining initial designs, but also for considering manufacturing tolerances which drive costs as well as for aiding the manufacturing process itself.

Well-established commercial design packages like OptiLayer™ for thin-film coating design and GSolver™ for grating design are used. PGL has also developed its own custom grating design software for maximum flexibility and speed. This software enables complex grating profiles to be modeled in a straightforward way, incorporating calculations of phase, polarization, and electric field enhancement. It is also capable of modeling two-dimensional (2D) gratings.

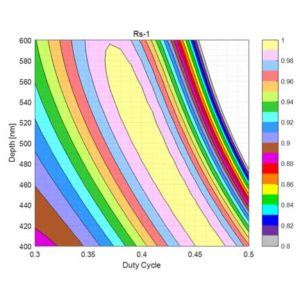

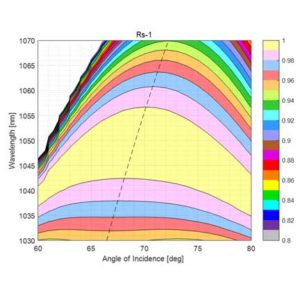

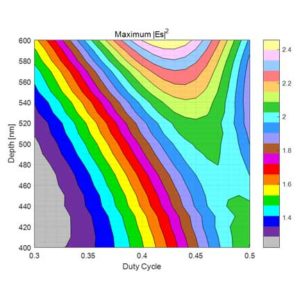

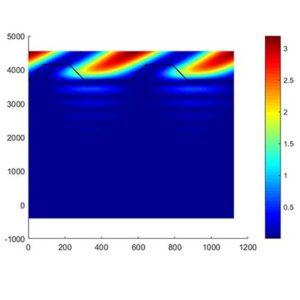

The example to the right shows how diffraction efficiency (DE) and normalized electric-field squared for an MLD grating depend on certain grating parameters (like depth and duty cycle) as well as use parameters (like wavelength and angle of incidence).

DE vs. Depth and Duty Cycle

(Wavelength = 1053 nm; AOI = 77.2º)

DE vs. Wavelength and AOI

(Depth = 460 nm; DC = 40%)

Max |E|2 vs. Depth and Duty Cycle

(Wavelength = 1053 nm; AOI = 77.2º)

Max |E|2 in the Grating

(Depth = 460 nm; DC = 40%)

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com